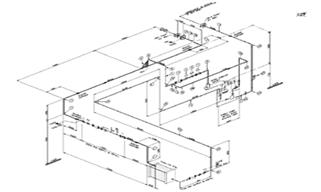

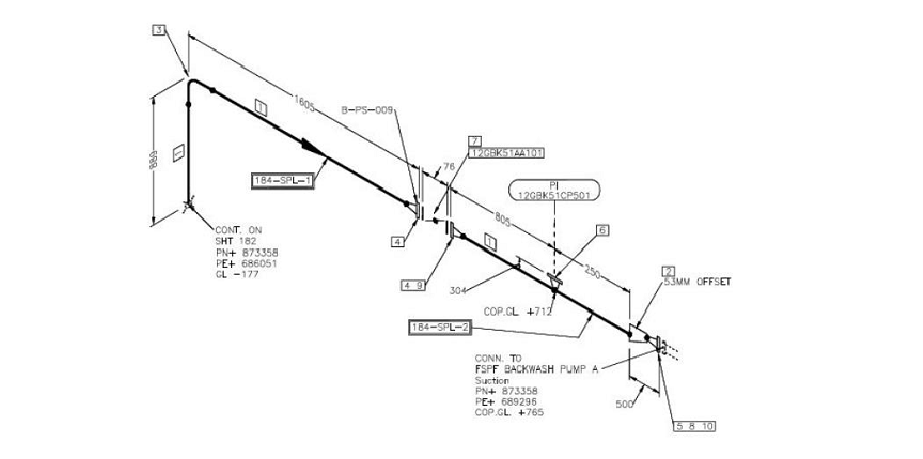

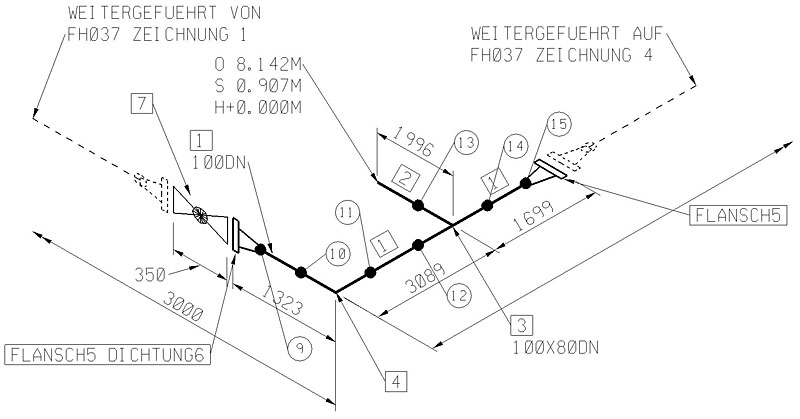

This kind of drawing helps a designer to transfer his vision of piping connections to the team executing. This is required for erection in the field.Ībove is an excerpt from the chapters of the book: Detail Engineering and Layout of Piping Systems 5th Edition. Here comes the role of Piping Isometric drawing. Dimensions to equipment and/or columns and a reference co-ordinate should be indicated on the iso.Spool pieces must be shipped in a container, thus the maximum size of a spool piece must fit into a shipping container measuring 40'x8'x8' (12m x 2.5m x 2.5m).

Similarly other flanged components such as valves, bolts and gaskets are shipped to the field by the supplier and assembled to the fabricated piping. The fab shop will make these individually and ship them to the field with individual mark numbers so that they can be erected in the correct connectivity. The iso may contain several "spool pieces" because of flanges or other breaks.Isos are drawn with the plant north arrow pointing to the top left or right of the drawing paper, depending on the clients standard preference.

0 kommentar(er)

0 kommentar(er)